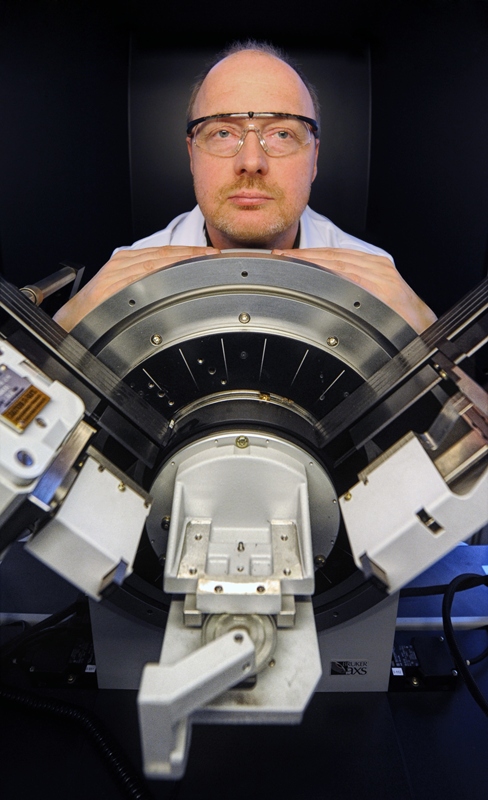

Opis zdjęcia

How one gelator molecule can immobilise as much as a few thousands of solvent molecules? Comprehensive understanding of the mechanism responsible for gel formation may open the way to the development of new materials and safer transportation methods of liquids that pose a risk to the environment. The structure of gels, however, can hardly be studied directly, as proven by experiments carried out at the Institute of Physical Chemistry of the Polish Academy of Sciences. Imagine two fully loaded oil tankers collide at a harbour entrance. Is then a massive environmental disaster unavoidable? Today, the most likely answer is: yes. In future, the collision may result in a twisted metal only. The oil will not get out because inside the tank it will have a form of a gel. Transportation of dangerous liquids in a gelled form is now a fantasy. It can not be excluded, however, that the future will bring gelling agents allowing for increased safety. To make it happen we have first to get a deeper insight into the internal structure of gels and the mechanisms of gel formation, says Dr Roman Luboradzki from the Institute of Physical Chemistry of the Polish Academy of Sciences (IPC PAS) in Warsaw. Gels are systems resembling more or less elastic jelly in appearance. Typically, they are two component systems: one component plays the role of a solvent whereas the second one acts as a gelator. In the gelling process (consisting in cooling down liquid mixture of both components), the gelator develops an extensive network in the gel space that immobilises the solvent. The network is mostly composed of amorphous structures resembling fibres or ribbons, and more rarely spherical structures in touch with each other. In chemical gels, gelator molecules attach to each other through strong covalent bonds, forming very rigid and durable structures. Physical gels, such as those studied at the IPC PAS, are formed following another principle. The gelator, usually an organic substance, contains small molecules composed of over a dozen to a few tens of atoms (thats why they are called: Low Molecular Mass Organic Gelators, LMOG). The molecules assembly to form long structures via weak noncovalent interactions including hydrogen bonding, pi-pi stacking, van der Waals forces, etc. The transition of a physical gel into a liquid and of a liquid into a gel are reversible processes. Usually, the transitions are very fast, and occur by changing temperature by only 1-2 degrees nearly the critical value. The analysis of gel structures, especially those of LMOG type, is difficult. Both gel components have often similar transparency and the structural details of the network are not larger than from over a dozen to a few tens of nanometers in size. A gel with such structure can not be examined under an optical microscope. And the scanning electron microscopy (SEM) requires to place a sample in vacuum. This requirement translates into a special preparation procedure of a gel sample for microscopic examinations. Researchers use two methods to guarantee that the structure of a gelator is preserved under a SEM microscope. The first one is to place the sample in a vacuum pump. Under lowered pressure the solvent quickly evaporates leaving a fixed gelator that typically looks like a white powder. The resulting structure is called xerogel. Xerogels are also produced using sublimation. In this method, the sample is rapidly frozen in liquid nitrogen. It is usually assumed that freezing of the sample occurs so fast the structure of the network formed by the gelator does not change. The frozen sample is then placed in a vacuum chamber where the solvent gradually sublimes. The problem is that some SEM images show crystals in xerogels that theoretically should not be present there. We didnt know if the crystals are a real part of the gel structure or rather a side-effect of the gel preparation procedure for microscopic studies. Thats why we decided to check how the xerogel structure changes with time and as a function of the method used to prepare samples for microscopic studies, says Dr Luboradzki. The results obtained at the Institute of Physical Chemistry of the PAS indicate that not always a SEM image corresponds to what is the original gelator structure in a gel. A necessary step of the sample preparation procedure for SEM studies is to evaporate a conductive layer on top of the sample. As the sample was locally warmed up in the process, the researchers were afraid that it may lead to changes in the xerogel structure. The evaporation tests with carbon, platinum, gold and palladium have shown, however, that the evaporation has no effect on the xerogel morphology. The researchers managed also to notice that the structure of some xerogels was dependent on the volume of the sample, and even on the shape of a vessel containing the sample. Xerogels prepared in a standard bottle contained more crystalline structures than the samples with volume ten times less but placed in capillaries. It was also observed that the transformation of amorphous fibres of finished gel into crystalline form could be speeded up by slightly warming up the sample. Moreover, after few months some xerogels developed spontaneous crystallisation. This means that even a properly prepared xerogel sample can essentially change its structure before it is placed in a SEM microscope. Xerogels are playing unfairly with researchers at least some of them are trying to cheat us. Now, being aware of that, we can avoid many misinterpretations and faster solve the riddle of how one small gelator molecule can efficiently bind even ten thousand solvent molecules, says Dr Luboradzki. This press release was prepared thanks to the NOBLESSE grant under the activity Research potential of the 7th Framework Programme of the European Union.

Komentarze

........ojoj .ja to się boję takich .......kosmicznych panófff................ :)

theWalker[ 2012-03-17 23:53:45 ] ==> Właśnie nie wiem ale oni potrafią zawsze coś wyskrobać :-)

za co?

Zaraz różni domorośli esteci Cię ucapią...